Specialized marine propulsion company, established in 2023. As an authorized distributor of QuantiCast for the Indonesian region, we offer a wide range of turnkey chocking and grouting solutions—covering every stage from design planning and calculations to material supply, on-site application, technical support, final hardness testing, and certification. Our proven system ensures secure and vibration-resistant installations for marine engines and heavy equipment, delivering reliability and performance in demanding operational environments.

To be a global leader in the provision of innovative and sustainable propulsion solutions to the marine and offshore industries, with a commitment to improving the efficiency, safety and operational performance of ships and maritime infrastructure worldwide.

Advancing efficient propulsion technology, delivering quality and reliability, minimizing environmental impact, building lasting client partnerships, driving sustainable growth through responsive services across the marine and offshore sectors.

Specifically designed for precision aligned engine plugging, QuantiCast comes as a two-component epoxy solution capable of withstanding the harshest environments. With high compressive strength, impact resistance, and chemical resistance to hydrocarbons and lubricants, it is the first choice for marine engine installations and heavy industrial equipment. The ideal thickness of between 10 - 70 mm makes QuantiCast flexible for a wide range of applications - from foundations of ship's main engines, gearboxes, alternators, rudders, pumps to fixation of stern tubes and support bearings. Not only for the maritime sector, QuantiCast is also efficient in industrial applications, including machine foundations, crane rails and outdoor structures.

| Main Physical Properties | ||

| Compressive Strength | 110 N/mm² (22,000 psi) | ISO 604 |

| Compressive Modulus | 2’760 N/mm² (400,000 psi) | ISO 604 |

| Tensile Strength | 38 N/mm² (5,500 psi) | ISO 527-2 |

| Barcol Hardness | > 35 | ASTM D-2583 |

| Specific Gravity | Resin 1.64 kg/ltr, Hardener 0.98 kg/ltr | |

| Maximum Temperature | 121 °C (250 °F) | |

| Pot Working Life | 10-15 min @ 25 °C | |

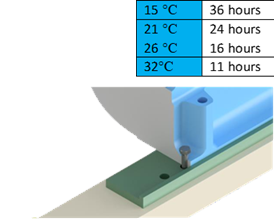

| Cure Time (approximately) | 24 hours @ 21 °C (70 °F) | |

| Packaging Size | 9.8 kg (21.5 lbs) kit | |

| Net Volume | 6.2 L | |

| Colour | Green | |

| Approvals | ABS, Bureau Veritas, ClassNK, DNV-GL, Lloyds Register, RINA | |

QuantiCast is engineered for optimal precision, with packaging designed to ensure the correct mix ratio—each resin bin matched perfectly with a corresponding hardener bottle. This standard combination suits nearly all application scenarios.

In rare cases, however, when the epoxy pour has minimal surface exposure relative to its volume, the heat generated during curing may not dissipate efficiently. This can trigger an uncontrolled exothermic reaction—where rising temperatures accelerate the cure too quickly, potentially causing cracks or surface distortion.

To manage such conditions, QuantiCast offers the flexibility to adjust the resin-to-hardener ratio depending on pour volume and ambient temperature. This ensures safe curing and structural integrity.

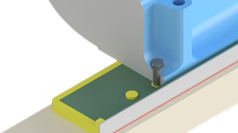

The pictures show the general damming procedure. The damming needs to be installed according to the chocking plan for the specific machine. Insert open cell foam strip on 3 sides, in the back and on the sides of the chock. Foam height has to be 6 mm higher than the chock thickness in order to ensure compression and maintain it firmly in place. Cut the foam 25 mm off the bedplate edge and spray the chock area with release agent. The exposed bolt holes have to be plugged by grease-covered protective foam to prevent them from filling up.

Install the front metal plate by tack welding and use silicone to seal or use epoxy putty. Put it in position at 16–19 mm from the bedplate edge. Metal plate height must be at least 40 mm greater than chock thickness. Install 2 pieces of foam to seal the front plate on the sides to prevent QuantiCast from overflowing. Spray the inside face of the front metal plate with release agent. Make sure to seal with silicone all possible leaking spots of the damming.

.jpg)

We provide engineers and service technicians to carry out QuantiCast installation work on board.